Sex Doll in Use

Tycoon of TPE Sex Dolls | WMDoll x AngelKiss Doll Factory Tour

We strongly recommend that you watch the accompanying video for this blog post, as it presents more detailed views of the dolls. Click the link to watch, and we appreciate your support.

First, let’s get a sense of the terrifying sales volume and scale of WM TPE dolls!

According to the WM sales director, WM’s monthly shipment volume is over 1000, but in WM’s history, the peak monthly sales of dolls have exceeded 2000.

Originally, a WM salesperson called Biscuit was guiding me around, but when I got here, I couldn’t help but record a video and accidentally left the Biscuit behind.

The finished TPE dolls are hung on racks, and walking through the aisles between the racks, you’ll be shocked by the overwhelming number of doll packaging boxes. Countless boxed dolls extend to the end of the entire floor.

This is what the WMDoll’s factory looked like in 2022 when I visited them.

And just one year later, they now own a whole new large industrial area.

Upon entering the industrial park, the building on the right hand side is where all WMDoll TPE dolls and their OEM brands like YLDoll, ORDoll, SEDoll etc., are produced. The super-large building directly in front of the entrance is a comprehensive building for the AngelKiss brand silicone doll production workshop, offices, and photography studio.

Let me first take you into the world’s most popular TPE doll production building, WMDoll Building 1.

On the first floor of the TPE building, we can see WMDoll’s mold storage area. According to the salesperson, several molds break every month, which shows how large WM’s shipment volume is.

Workers secure the skeleton within the mold.

This is a mold of a seamless sex doll.

This is a doll mold with a heating function, where workers bind heating wires on the skeleton.

We can also see some original clay head sculptures, each with unique characteristics.

After the skeleton is fixed in the mold, workers pour hot TPE material into it, and then it’s time to wait for the TPE liquid to cool. To speed up the cooling process, WMDoll has a large cold storage, something I haven’t seen in other factories.

Using a crane, the mold filled with TPE material is dragged into the cold storage, and after cooling overnight, the doll mold comes out from the other end of the cold storage, ready for demolding.

After demolding, since the mold seams leave excess TPE material on the sides of the doll, workers use heat to remove the excess TPE material from the sides.

All the workers in this production segment are women.

After the trimming is completed, since the TPE material is very shiny, the body and head need to be powdered and made up to make the doll’s skin look more like real human skin. The makeup for the heads is also done by women.

After strict quality inspection, the factory takes photos of the dolls and sends them to the customers who placed the orders for confirmation. Once confirmed, they can be shipped.

Some dolls have just been boxed, while others are piled up together. You can notice WM’s most popular doll, 166C.

Of course, there are also whole boxes of doll heads S273 ready to be shipped to overseas warehouses.

There’s not only a storage area for bodies but also for heads, where we can see a distinctive hard TPE head. This hardened TPE head allows for hair implantation.

Not just bodies and heads, the storage volume of penises and inserts is also quite astonishing.

In WM’s TPE building, I had the rare opportunity to witness the processing of a new mold.

According to the introduction, WMDoll has a cooperative European design team that provides WMDoll with designed female body 3D files. The WM factory produces molds based on the printed 3D models, with workers covering the 3D human figure with a clay-like substance, eventually producing molds usable for sex doll production.

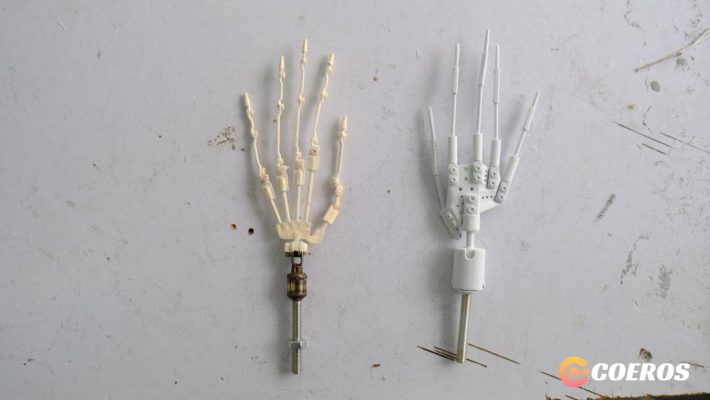

I also discovered some interesting accessories in this building, such as WMDoll’s self-developed cleaner and upgraded finger bones.

This is a comparison between the upgraded finger bones and traditional finger bones.

Additionally, WM has a special accessories hardware room for the development and production of accessories.

Opposite the TPE building are the dormitories and dining hall for the staff.

However, the most impressive and shocking thing I found in this building was this.

This is WM’s founding product. Before inventing the full-body TPE doll in 2012, WM initially produced clothing models using TPE material, and surprisingly, they are still producing them in 2023. It seems this clothing store has also walked hand in hand with WM for over 10 years.

Then, we move to Building 2, the silicone building, where Angel Kiss and other OEM brands’ silicone dolls are produced.

WMDoll and AngelKiss are independent brands of Jin San factory, with WM mainly producing TPE dolls, while AngelKiss only produces silicone dolls.

On the first floor of this building is the skeleton production area, where these staff are responsible for producing all the skeletons needed for the entire factory, including AngelKiss and WMDoll. Since it’s on the first floor and very close to the TPE production building, the skeletons needed for TPE dolls can be conveniently transported there.

Going upstairs, we see rows of stored Angel Kiss silicone dolls. The storage area and number of workers for silicone dolls are less compared to the TPE building.

Since this was my first time seeing Angel Kiss dolls, I tested the softness of a few dolls on site. Surprisingly, the softness of the breasts of AngelKiss silicone dolls is extremely soft, even surpassing some common silicone brands’ Gel Breasts. Among the dolls I’ve tested, only Irokebijin’s softness is comparable. In contrast, other parts are harder, including the buttocks, with no gel buttock option. Unlike WMDoll, a long-established, well-known, and widely popular brand, Angel Kiss is still an emerging brand in the silicone doll market.

Next to it is the head mold storage area, while the silicone body molds are stored in a separate room.

We also saw a worker operating a silicone doll body mold. He needs to fix the finger bones and skeleton inside the mold with wires before pouring the material for production. The white part of this skeleton is a foaming material used to reduce the weight of the silicone doll.

After demolding, the silicone dolls also need makeup.

We saw a worker painting the body, but after careful inspection, I think the makeup level of Angel Kiss could be more realistic.

This is the workstation for doll head makeup.

On the fourth floor of the silicone building is WMDoll’s office.

Exiting the elevator, you can see an unfinished showroom with a few WMDoll dolls.

In the middle of the hall is the office space, with a display wall showcasing some of the company’s awards and certificates.

The foreign trade department enjoys a separate office.

In a meeting room, there’s a doll sitting alone, looking lonely, as if waiting for someone.

Behind the display wall, we find the logos of WMDoll and Jinsan, and photography studios for taking promotional pictures of dolls, and of course, a live broadcast room.

According to the salesperson, due to video platform policy restrictions, these dolls can only be used as background props, not as products for explanation.

This pretty much sums up the full view of the WMDoll and AngelKiss factory. Of course, during my visit, the WMdoll sales director told me that in response to the release and price reduction of the Zelex SLE series, Wmdoll and AngelKiss will not just watch the market being gradually occupied by other brands. They will also find ways to make some new breakthroughs. Unexpectedly, less than two months after I finished my visit and returned, WMdoll’s STPE material has already been released. I am very much looking forward to testing a WMdoll made of STPE material or an Angel Kiss Silicone Doll.